资讯

-

科技期刊编辑视角下的论文写作与发表数学学院内容简介

科技期刊编辑视角下的论文写作与发表数学学院内容简介 -

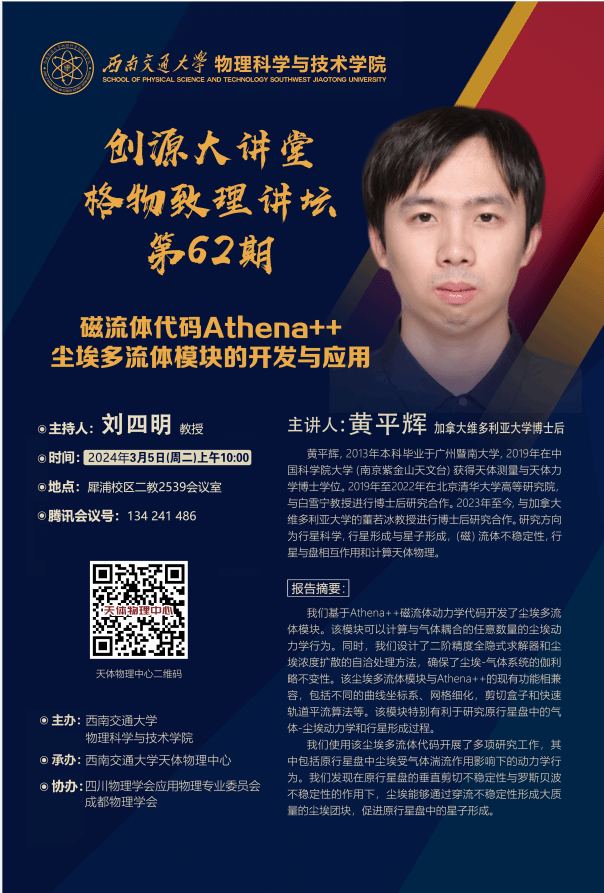

【创源大讲堂】磁流体代码Athena++尘埃多流体模块的开发与应用物理科学与技术学院2024年3月5日(周二)10:00犀浦校区二教2539会议室黄平辉,加拿大维多利亚大学博士后内容简介我们基于Athena++磁流体动力学代码开发了尘埃多流体模块。该模块可以计算与气体耦合的任意数量的尘埃动力学行为。同时,我们设计了二阶精度全隐式求解器和尘埃浓度扩散的自洽处理方法,确保了尘埃-气体系统的伽利略不变性。该尘埃多流体模块与Athena++的现有功能相兼容,包括不同的曲线坐标系、网格细化,剪切盒子和快速轨道平流算法等。该模块特别有利于研究原行星盘中的气体-尘埃动力学和行星形成过程。 我们使用该尘埃多流体代码开展了多项研究工作,其中包括原行星盘中尘埃受气体湍流作用影响下的动力学行为。我们发现在原行星盘的垂直剪切不稳定性与罗斯贝波不稳定性的作用下,尘埃能够通过穿流不稳定性形成大质量的尘埃团块,促进原行星盘中的星子形成。

【创源大讲堂】磁流体代码Athena++尘埃多流体模块的开发与应用物理科学与技术学院2024年3月5日(周二)10:00犀浦校区二教2539会议室黄平辉,加拿大维多利亚大学博士后内容简介我们基于Athena++磁流体动力学代码开发了尘埃多流体模块。该模块可以计算与气体耦合的任意数量的尘埃动力学行为。同时,我们设计了二阶精度全隐式求解器和尘埃浓度扩散的自洽处理方法,确保了尘埃-气体系统的伽利略不变性。该尘埃多流体模块与Athena++的现有功能相兼容,包括不同的曲线坐标系、网格细化,剪切盒子和快速轨道平流算法等。该模块特别有利于研究原行星盘中的气体-尘埃动力学和行星形成过程。 我们使用该尘埃多流体代码开展了多项研究工作,其中包括原行星盘中尘埃受气体湍流作用影响下的动力学行为。我们发现在原行星盘的垂直剪切不稳定性与罗斯贝波不稳定性的作用下,尘埃能够通过穿流不稳定性形成大质量的尘埃团块,促进原行星盘中的星子形成。 -

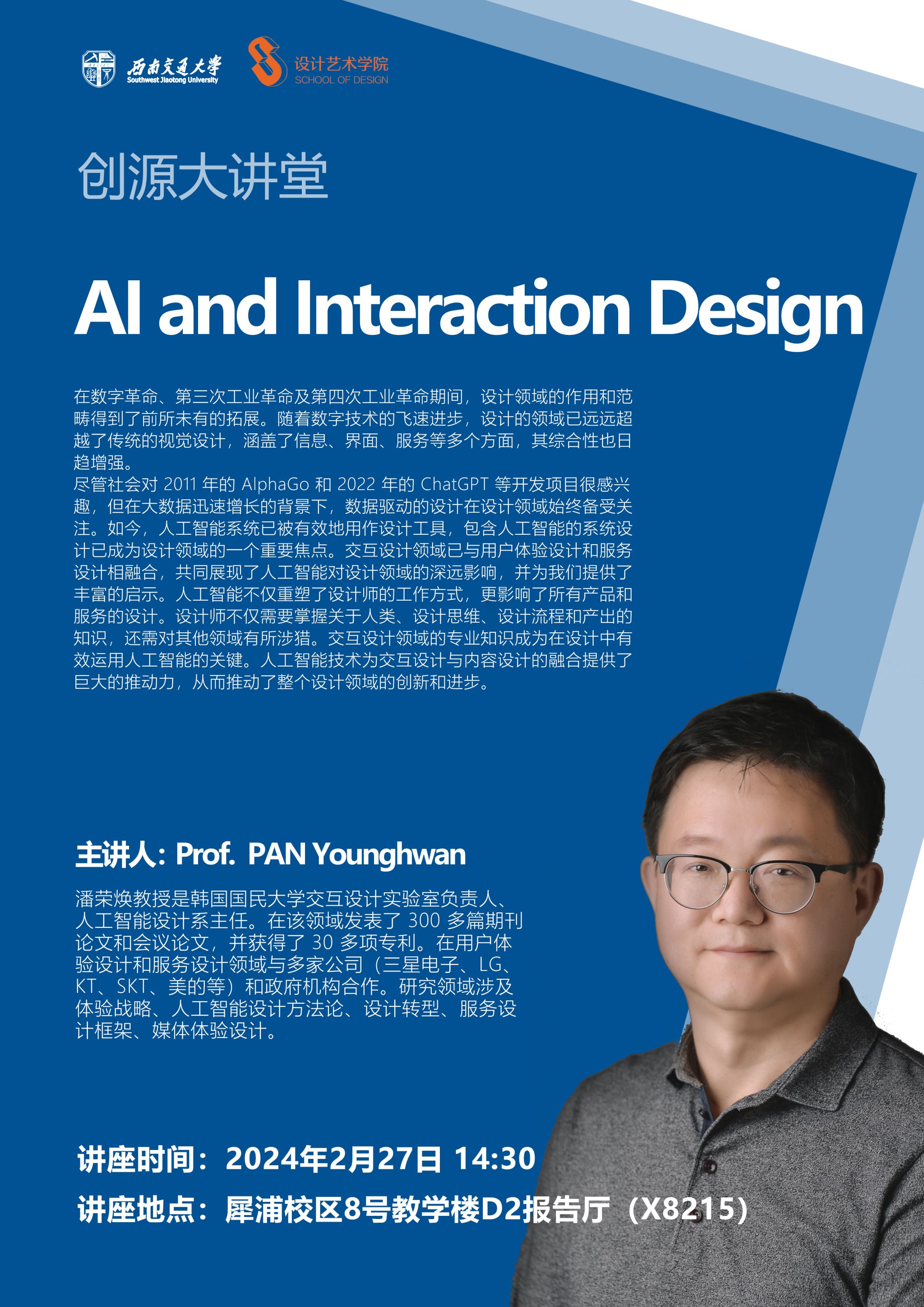

【创源大讲堂】AI and Interaction Design设计艺术学院2024年2月27日14:30西南交通大学犀浦校区D2报告厅(X8215)PAN Younghwan (潘荣焕)内容简介

【创源大讲堂】AI and Interaction Design设计艺术学院2024年2月27日14:30西南交通大学犀浦校区D2报告厅(X8215)PAN Younghwan (潘荣焕)内容简介 -

【创源大讲堂】Chandra X射线观测超新星遗迹N132D激波膨胀速度测量物理科学与技术学院2024年1月23日10:00犀浦校区二教2539龙曦 哈佛史密森天体物理中心博士后内容简介超新星遗迹是恒星演化末期,发生爆炸后,抛射出来的恒星物质,以及爆炸时产生的激波与星际介质相互作用形成的结构。超新星遗迹被认为是银河系中“膝区”宇宙射线的一个重要来源。超新星爆炸把重元素(如铁、金等)送入星际空间。超新星遗迹可以通过其动力学过程影响周围介质的结构和演化。超新星遗迹N132D,是大麦哲伦星云中在X射线能段最亮的超新星遗迹。我们在N132D的两个位置测量了激波的膨胀的速度。其中一个区域由激波速度推导出的温度与从X射线能谱拟合得到的温度之间的明显差异可以通过离子和电子之间的温度部分平衡,绝热膨胀的冷却效应来解释。在另一区域这两个效应不能解释这种温度差异,因此我们讨论了宇宙线粒子加速解释这个差异的可能性。同时利用我们测量的激波半径和速度,以及激波一维演化模型,我们可以限制超新星遗迹周围介质的密度分布,超新星爆炸能量,以及抛射射物质量。

【创源大讲堂】Chandra X射线观测超新星遗迹N132D激波膨胀速度测量物理科学与技术学院2024年1月23日10:00犀浦校区二教2539龙曦 哈佛史密森天体物理中心博士后内容简介超新星遗迹是恒星演化末期,发生爆炸后,抛射出来的恒星物质,以及爆炸时产生的激波与星际介质相互作用形成的结构。超新星遗迹被认为是银河系中“膝区”宇宙射线的一个重要来源。超新星爆炸把重元素(如铁、金等)送入星际空间。超新星遗迹可以通过其动力学过程影响周围介质的结构和演化。超新星遗迹N132D,是大麦哲伦星云中在X射线能段最亮的超新星遗迹。我们在N132D的两个位置测量了激波的膨胀的速度。其中一个区域由激波速度推导出的温度与从X射线能谱拟合得到的温度之间的明显差异可以通过离子和电子之间的温度部分平衡,绝热膨胀的冷却效应来解释。在另一区域这两个效应不能解释这种温度差异,因此我们讨论了宇宙线粒子加速解释这个差异的可能性。同时利用我们测量的激波半径和速度,以及激波一维演化模型,我们可以限制超新星遗迹周围介质的密度分布,超新星爆炸能量,以及抛射射物质量。 -

【创源大讲堂】Quadratic forms, vectorial bent functions and linear codes数学学院2024年1月18日上午11:00西南交通大学犀浦校区7510欧阳毅内容简介

【创源大讲堂】Quadratic forms, vectorial bent functions and linear codes数学学院2024年1月18日上午11:00西南交通大学犀浦校区7510欧阳毅内容简介 -

【创源大讲堂】Generator polynomials of cyclic expurgated or extended Goppa codes数学学院2024年1月18日上午10:00西南交通大学犀浦校区7510岳勤内容简介

【创源大讲堂】Generator polynomials of cyclic expurgated or extended Goppa codes数学学院2024年1月18日上午10:00西南交通大学犀浦校区7510岳勤内容简介 -

【创源大讲堂】New product formulas for classical Gauss sums数学学院2024年1月18日上午9:00西南交通大学犀浦校区7510张文鹏内容简介

【创源大讲堂】New product formulas for classical Gauss sums数学学院2024年1月18日上午9:00西南交通大学犀浦校区7510张文鹏内容简介 -

不确定性数学理论的热点问题研究数学学院内容简介

不确定性数学理论的热点问题研究数学学院内容简介 -

Fuzzy sets as enriched categories数学学院内容简介

Fuzzy sets as enriched categories数学学院内容简介 -

Cartesian closed and stable subconstructs of Ord数学学院内容简介

Cartesian closed and stable subconstructs of Ord数学学院内容简介